Family Commuter Car Review: 2025 Neta X Compact Electric SUV - Performance, Comfort, and Cost Analysis

- 541

- 15 April 2025

A $280,000 car costs $200,000 to repair after hitting a wall corner! What s so great about the trouble-causing integrated casting?

In the past year or two, domestic new energy vehicle technology has continued to advance, while product prices have also been steadily declining. The completeness of the supply chain and intense competition are undoubtedly the main reasons. Additionally, automakers are fiercely competing in manufacturing processes, particularly in the area of integrated die-casting technology. Companies like Tesla and Xiaomi have already adopted this technology. However, since Tesla first implemented integrated die-casting in the Model Y, many consumers have yet to fully grasp the advantages of this innovation. On the contrary, some car owners have quickly learned its downsides the hard way!

I wonder if you still remember a highly representative single-vehicle accident that went viral online a year or two ago. A Tesla Model Y owner was parking in a residential area when, possibly due to distraction or limited driving skills, the car’s rear end collided directly with the 90-degree corner of a building during reversing. The impact was visibly severe—the left side of the vehicle suffered extensive damage, and the rear wheel nearly ended up pressed flat against the wall.

Of course, it s normal for any car or driver to be involved in an accident. What drew attention at the time was that Tesla s after-sales service quoted a repair cost of 200,000 yuan for this accident vehicle. According to the owner, the car itself was only worth 280,000 yuan—a 280,000-yuan car requiring 200,000 yuan in major repairs was simply outrageous! The reason for such a high repair quote was that the integrated die-cast component had suffered relatively severe damage, leading to the exorbitant repair costs.

So, once an accident occurs, the repair costs for vehicles with integrated die-casting are so high, and users don’t even perceive any advanced benefits during daily driving. Why are car manufacturers still pushing so hard for integrated die-casting?

The first consideration is cost. For car manufacturers, simpler structures lead to greater cost savings. Why? Because more components require additional processes and procedures. Whether it s monitoring workflows or certain steps needing manual intervention, an increase in parts inevitably means higher labor costs.

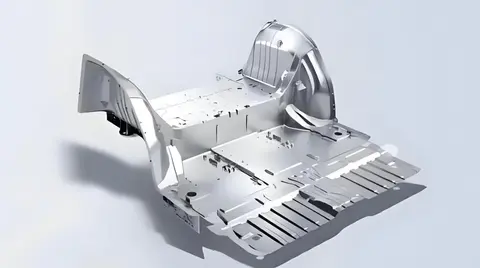

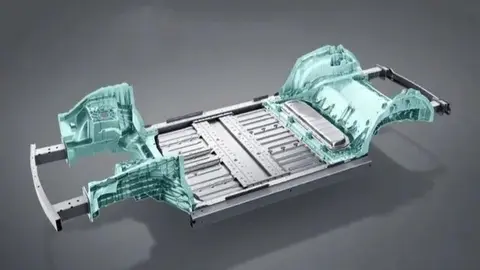

However, integrated die-casting technology is different. Simply put, many related components are directly cast together in one piece, eliminating the need for re-welding or screw connections, which significantly reduces the number of parts. As a result, costs are greatly reduced. For manufacturers, overall costs are lowered, making it more advantageous to reduce prices and wage a price war more effectively!

Another point is product consistency. As mentioned earlier, the more components there are, the more connection points there will be. With more connectors, the risks of loosening, abnormal noises, and even mechanical fatigue become greater—this should be understandable to everyone!

For integrated die-casting technology, the core material used is higher-strength aluminum alloy. The aluminum alloy is die-cast into a small number of components, which not only significantly reduces the number of connectors but also enhances the strength of these large parts. As a result, integrated die-cast components exhibit greater overall consistency and a lower probability of minor issues, leading to improved vehicle performance, smoother operation, and greater reliability.

So, from the manufacturer s perspective, although the price of aluminum alloy material itself is higher than that of steel, and the cost of die-casting machines is also substantial, from the standpoint of decreasing costs, integrated die-casting technology can improve the vehicle s consistency in performance while also reducing the per-unit cost. Essentially, for consumers, purchasing a vehicle equipped with integrated die-casting technology is still quite cost-effective.

Therefore, while extreme incidents like the previous Tesla Model Y accident do incur higher repair costs, such cases are exceptions. In the vast majority of situations, users still benefit from the integrated casting technology.